Six Virtual Use Cases will analyse potential configurations for integrating the RESTORE technology and RES into different plants connected to DHC networks, spread over different locations in Europe:

Use Case I – Brønderslev, Denmark

- Use Case Area of Application: district heating for the city of Brønderslev, biomass and solar collectors as renewable technologies to provide heat to the district.

- Expected goals for achievement: maximization of renewable energy integration in the district and optimum waste heat utilization from local industry for highly efficient seasonal storage of electricity.

Use Case Description:

As a pioneer in the field of smart energy Brønderslev Forsyning A/S is implementing a “District Heating of the Future” concept: power and district heating supply is generated in its own combined heat and power unit which is one of the most efficient plants worldwide due to the combination of solar, biomass and heat pumps.

Brønderslev Forsyning developed this CHP plant located in Denmark. First Brønderslev Forsyning A/S district heating company carried out a comprehensive feasibility study. Subsequently they established a 0.8 MWth test facility to investigate the potential of using concentrated solar power (CSP) as an add-on to a biomass-fired Organic Rankine Cycle (ORC) plant. Based on the positive findings, they started the contraction of a CSP plant to supply 16.6 MWth enabling production of heat and electricity within one carbon-free system. The plant is in operation since March 2018.

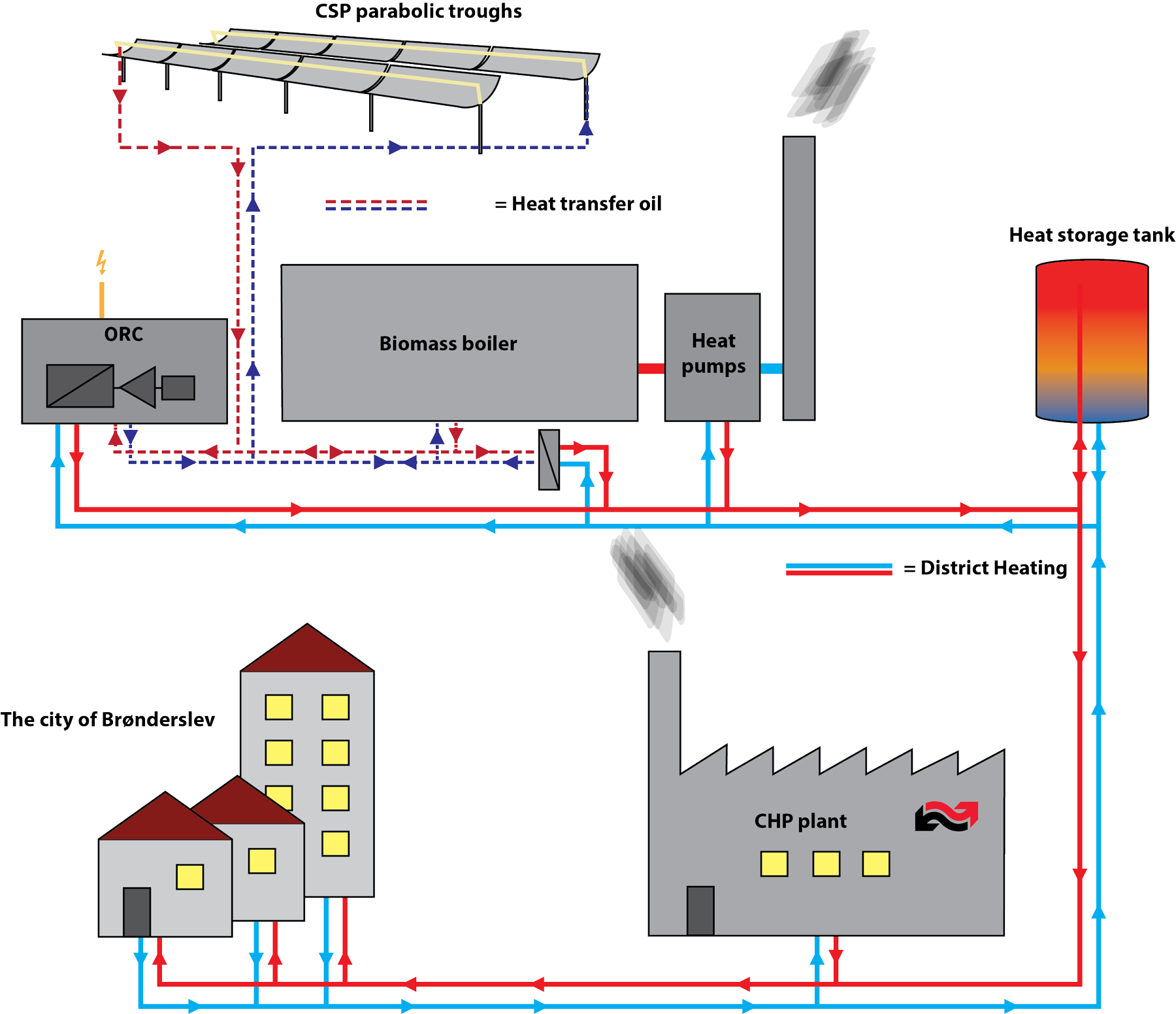

Bronderslev process integration scheme

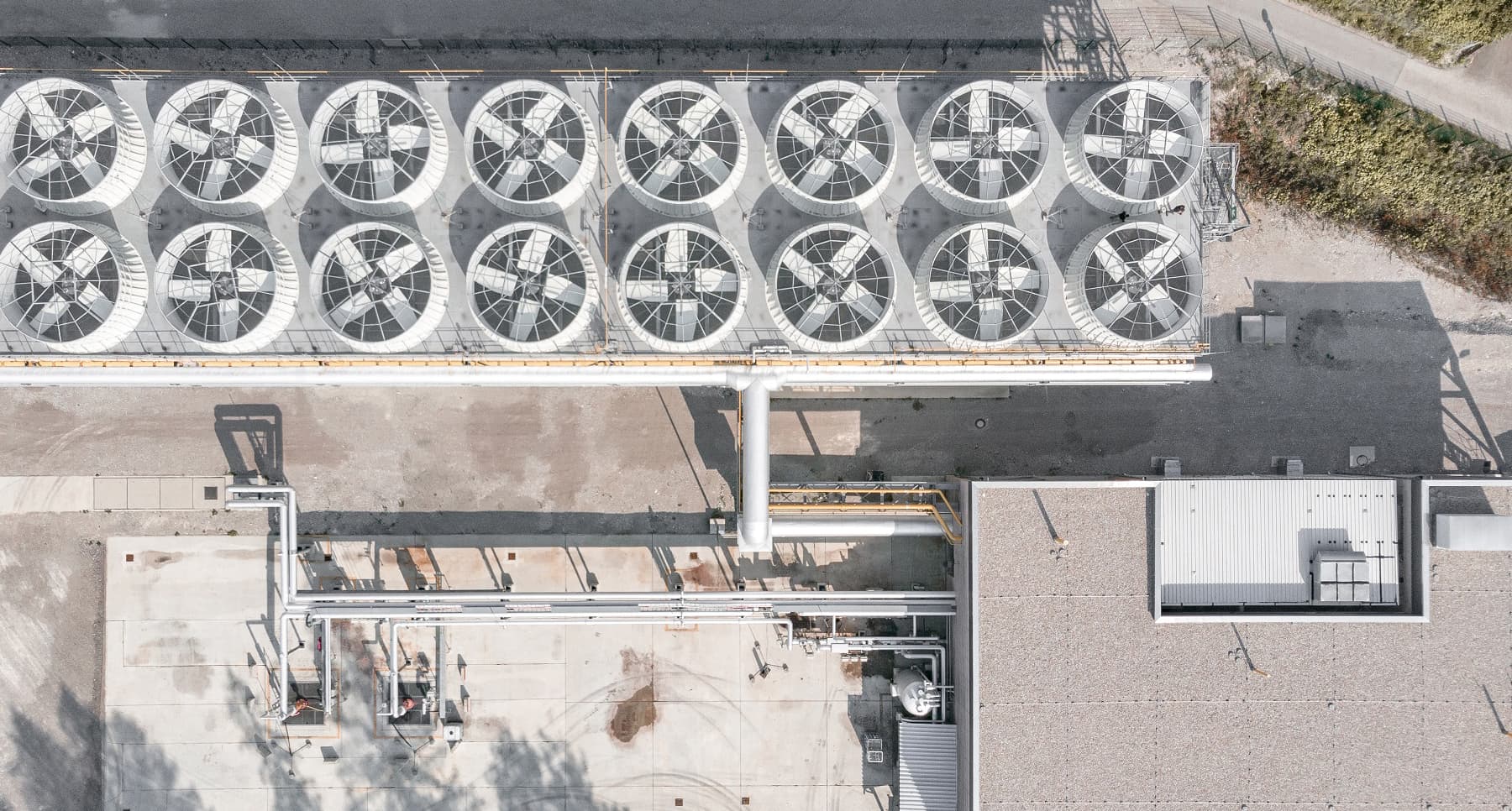

Solar energy plant:

The solar energy plant is based on the CSP parabolic trough technology consisting of 40 rows of 125 m U-shaped mirrors with an aperture area of 26,929 m2. These mirrors collect the sunrays throughout the day and reflect them onto a receiver pipe, which sums up to 5 kilometre receiver tubes. This receiver pipe is surrounded by a special glass vacuum tube. Inside this runs – only heated by the sun – thermal oil with temperatures up to 330 °C. This high temperature is able to drive an electric turbine to produce electricity. Besides, the flexibility of the system allows production of lower temperatures for district heating purposes. The solar heating system can thus alternate between providing heat or power. To maximize yield of energy, the waste heat is utilized and sent to the district heating circuit whereas electrical power is generated at peak price periods. On sunny days, the solar-thermal system is set to reach 16.6 MWth capacity.

Bronderslev Full plant overview (solar field)

Bronderslev Full plant overview (ORC and natural gas CHP)

The ORC system has about 3.8 MWel fed by thermal oil coming both from the 2 biomass boilers and the concentrated solar field. Part of the thermal power from CSP is used directly to heat up district heating water. ORC equipment selected is TURBODEN 40 CHPRS SPLIT. Water temperature (in/on): 50-72ºC.

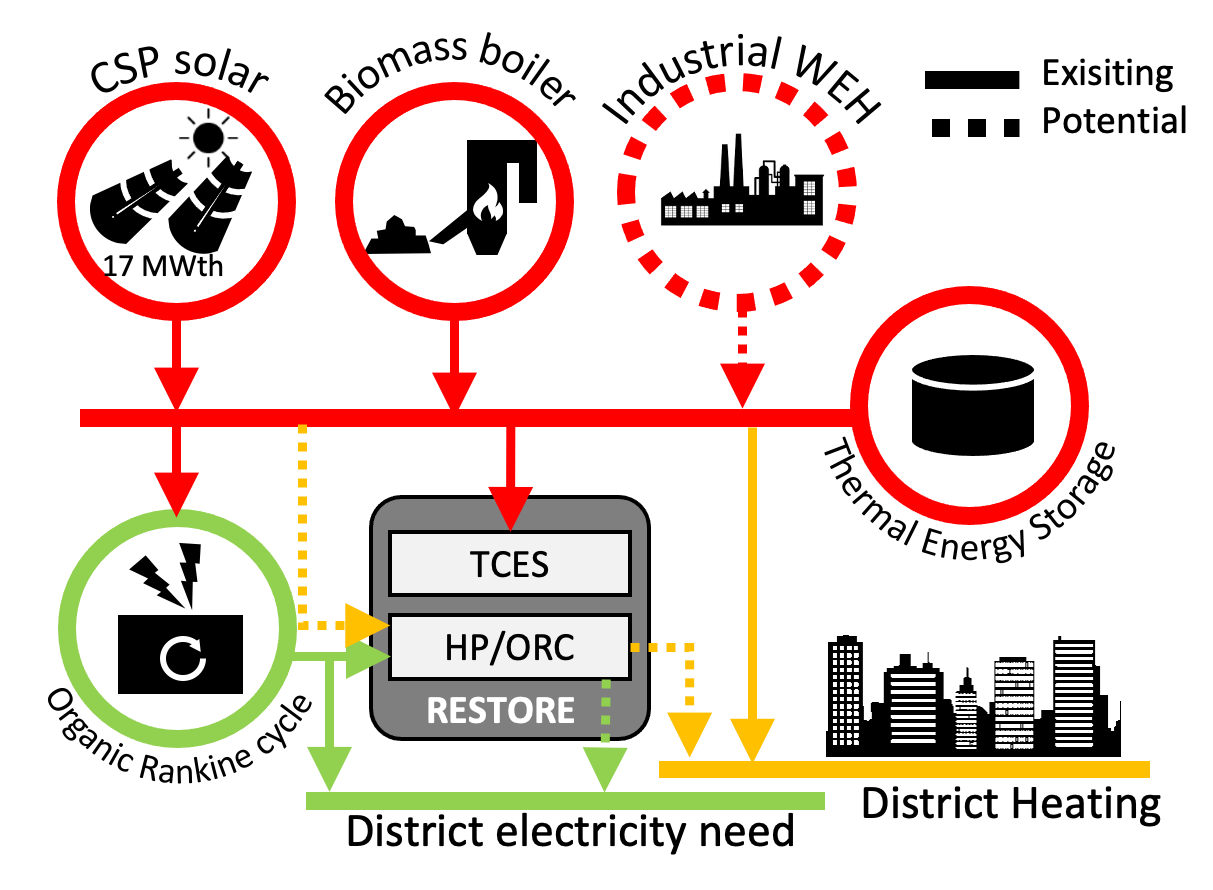

RESTORE proposed solution:

The virtual pilot will integrate a specifically optimized RESTORE energy storage unit. The existing parabolic trough solar collector field can then charge the TCES system during summer months. Besides, residual heat from industry or excess low-temperature heat from solar collectors in the district serves to efficiently store off-peak cheap electricity.

RESTORE proposed solution Brønderslev

Community addressed:

Brønderslev Forsyning A/S holding company is responsible for the district heating and water supply, as well as for wastewater treatment of the Danish city of Brønderslev, located in the northernmost part of the Jutland peninsula in northern Denmark. The company is owned 100% by the city municipality. The district heating network supplies about 4,600 customers and has a length of around 140 km.

Use-Case II - Gmunden, Austria

- Use Case Area of Application: analysis of potential configurations of integrating the RESTORE technology into the cement production plant and its relation to the neighbouring heat consumers.

- Expected goals for achievement: maximization of renewable energy integration and optimum WEH utilization from the factory for highly efficient seasonal storage of electricity using RESTORE.

Use Case Description:

The Gmunden site cement plant of RD group has currently the capacity of around 1.900 ton/day of cement clinker, with a district heating connection (capacity of ~8 MWth). The clinker process offers multiple options of heat integration with district heating and cooling. Waste excess heat either comes from air cooled clinker coolers, or from the off gas from cyclone tower. In the case of a waste heat steam cycle plant such as in the Rohrdorf site, also using extraction steam from a steam turbine is possible which itself is fed by steam from the waste heat recovery steam generator.

The installation of a waste heat steam generator is under consideration in the frame of a national research project. The state-of-the-art cement factory in Gmunden produces huge amounts of WEH that cannot be used by the cement production process itself. Its recent connection to a local district heating network allowed 8 MW thermal power to be provided covering the heat demand for roughly 1,000 homes. Nevertheless, additional excess heat is available, especially during the summer months without space heating need.

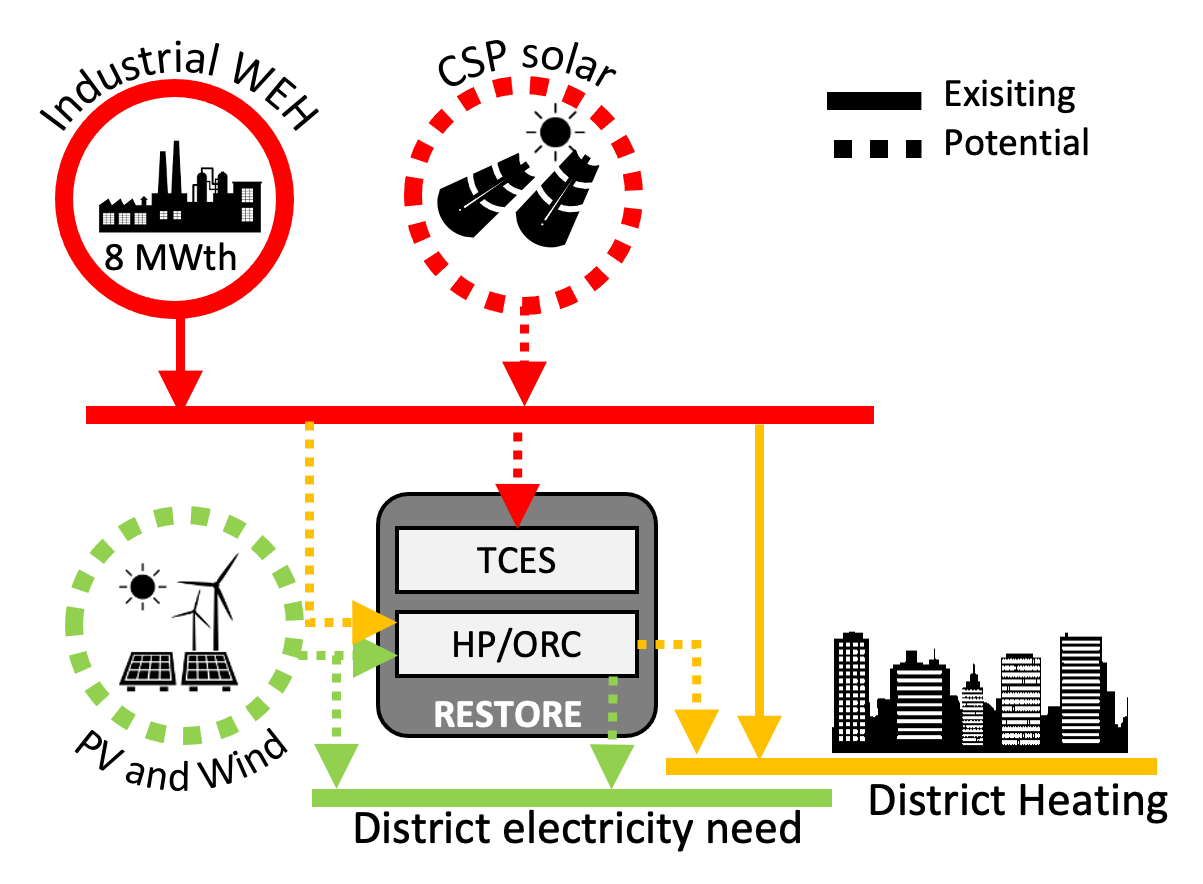

RESTORE proposed solution:

The virtual pilot will simulate the integration of the RESTORE developed concept within the industrial plant. The aim is to maximize WEH utilization and RES integration for seasonal storage of heat using cheap off-peak electricity.

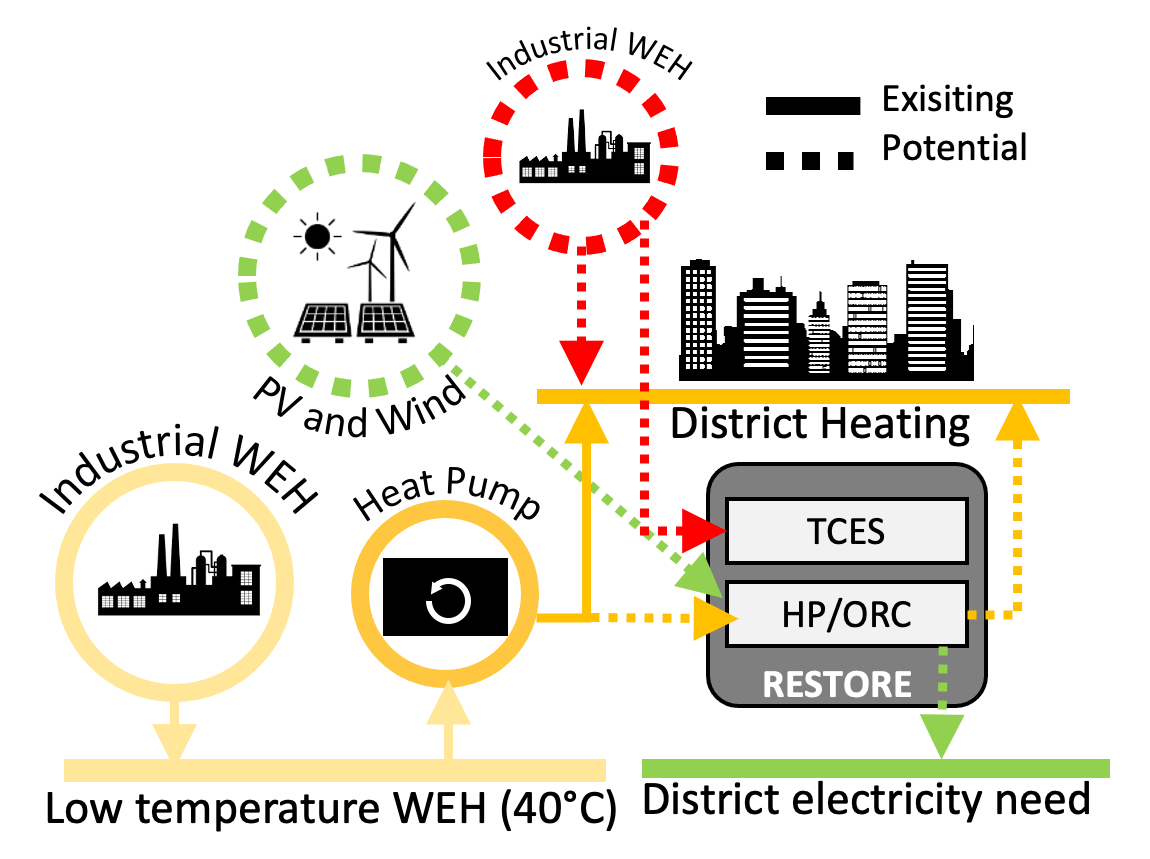

RESTORE proposed solution Gmunden

Community addressed:

The Austrian cement industry incorporates nine integrated cement plants and two grinding mills spread across the country, including the Gmunder Zement’s Hatschek plant. The communities involved are the core stakeholders in the site of Gmunden, for instance adjacent industrial companies, municipalities and regional authorities. Apart from the regional expected impact, RESTORE Use Case II will be a relevant reference on a wider sense, at national and European scales for the cement industry.

Use Case III - Ružomberok, Slovakia

- Use Case Area of Application: analysis of potential configurations for integrating the RESTORE technology into plants of the pulp and paper industry connected to DH and RES.

- Expected goals for achievement: maximize the renewable energy integration and optimize WEH utilization from the factory for highly efficient seasonal heat storage.

Use Case Description:

Mondi SCP in Ružomberok is one of Mondi’s largest plants and is the biggest integrated mill producing paper and pulp in the Slovak Republic. It has a production capacity of 560,000 tonnes of uncoated fine paper, 66,000 tonnes of packaging paper and 100,000 tonnes of market pulp. After its latest investment into a new recovery boiler, the mill is 100% energy self-sufficient with over 94% of its energy coming from renewable resources. The wood comes from certified, well-managed forests.

The production continuously decreases footprint on the environment. Part of the heat produced by the Mondi mill supplies the district heating system in the form of 5 bar steam. Steam enters a heat exchanger station, where heat exchangers transfer heat into water. Hot water is pumped via a distribution network into the city, through local heat exchangers and is flowing back to the steam/water heat exchanger station to gain heat again.

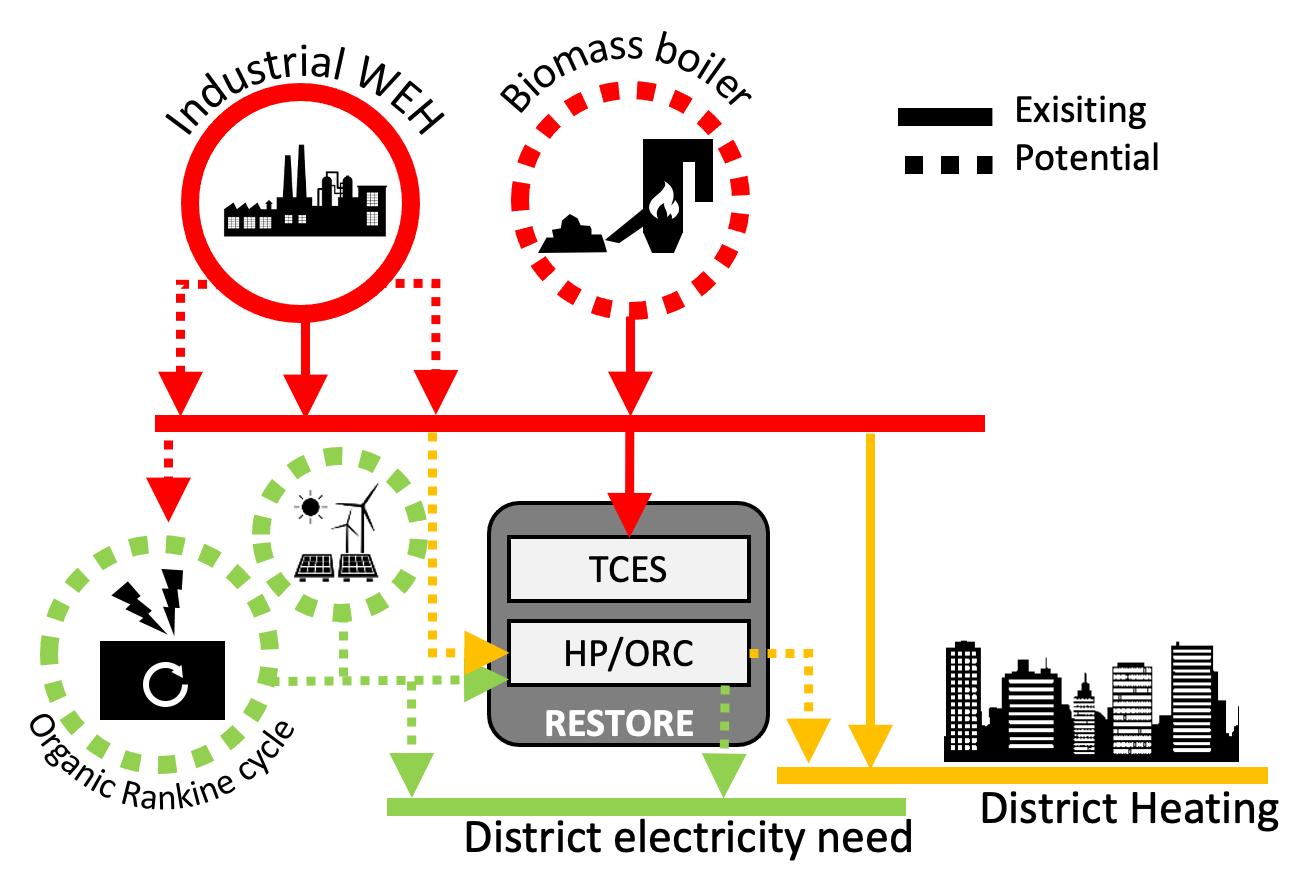

RESTORE proposed solution:

The utilization of the following energy sources will be explored and integrated in RESTORE concept to store heat on seasonal base: (i) waste steam in case of reduced heat demand in district heating; (ii) flue gas recovery from boilers at LT which is not used so far; (iii) hot water streams available at site which may be used for water preheating or HP energy input. The expected outcome is thus a huge reduction of the GHG through a high increment in the RES share and the waste heat capacity factor.

RESTORE proposed solution Mondi

Community addressed:

The mill has been producing paper in Ružomberok for over 300 years. The abundance of the raw materials like wood, water, and energy has had a favourable influence on the development of the mill. In early years, the mill was far away from residential areas. But in the course of urban development, the city has spread and the mill is now in the heart of the Ružomberok area, which embeds 49,035 km2 with 40.84% of forest land and a population of ~5.4 million. The main industries of the region are: automobile, chemical, iron ore processing, and pulp and paper.

Use Case IV - BRESCIA, Italy

- Use Case Area of Application: the use case will apply the RESTORE concept to a DHC network linked to one of the largest electric arc furnace steel mills in Italy

- Expected goals for achievement: achieve higher efficiency of Alfa Acciai production process, improve HP utilization during summer season and increase share on local DH.

Use Case Description:

Alfa Acciai is one of the largest Electric Arc Furnace Steel Mill in Italy. It started producing steel in Brescia in the mid 1950’s. It soon became a benchmark in the industry and the construction sector at a time of rapid social and economic growth. The installation of a continuous casting system and heavy investments in new technology allowed the company to step up the production capacity in both the steel mill and rolling mill.

The Alfa Acciai Group has been orienting increasingly towards customer service, by focusing on the production of steel for the reinforcement of concrete, while respecting the environment and the worker health and safety in the workplace.

In recent years, the Alfa Acciai group became one of Europe’s leading producers of reinforcing steel for the construction industry. The community of Brescia profit directly from the continuous growth of the company and its innovations.

RESTORE proposed solution:

Alfa Acciai site in Brescia is composed by 2 electric arc furnace units and 3 rolling mills. The current strategy for waste heat recovery system is based on a large HP able to recover waste heat from the cooling system of the “pipe to pipe” circuit of the furnaces. The temperature of available heat is in the range of 30°-40°C. By upgrading it up to 90°C through the HP, the excess heat will supply a district heating network of Brescia instead of being wasted. Distributing the heat to the final users will thus satisfy the heat demand in a smart and green way.

RESTORE proposed solution Brescia

Use Case V - Holzkirchen, Germany

- Use-Case Area of Application: the use case will apply the RESTORE concept to a DHC network (local utility of Holzkirchen) with geothermal technology.

- Expected goals for achievement: maximization of the geothermal heat exploitation and optimum WEH utilization for highly efficient seasonal storage of heat.

Use Case Description:

Geothermie Holzkirchen GmbH is a wholly owned subsidiary of the local utility of Holzkirchen, a town located in the south of Munich, Germany. The existing conditions for developing geothermal energy are particularly favourable in the southern German Molasse basin, as there is particularly hot water at the appropriate depth (500 meters). Heat can be used as direct supply to district heating. Moreover, from a temperature of around 120 degrees celsius, electricity production is possible. In the long term geothermal energy will cover up to 80 percent of Holzkirchen’s district heating network demand. This equivalents to avoiding around 10,000 tons of climate-damaging carbon dioxide every year.

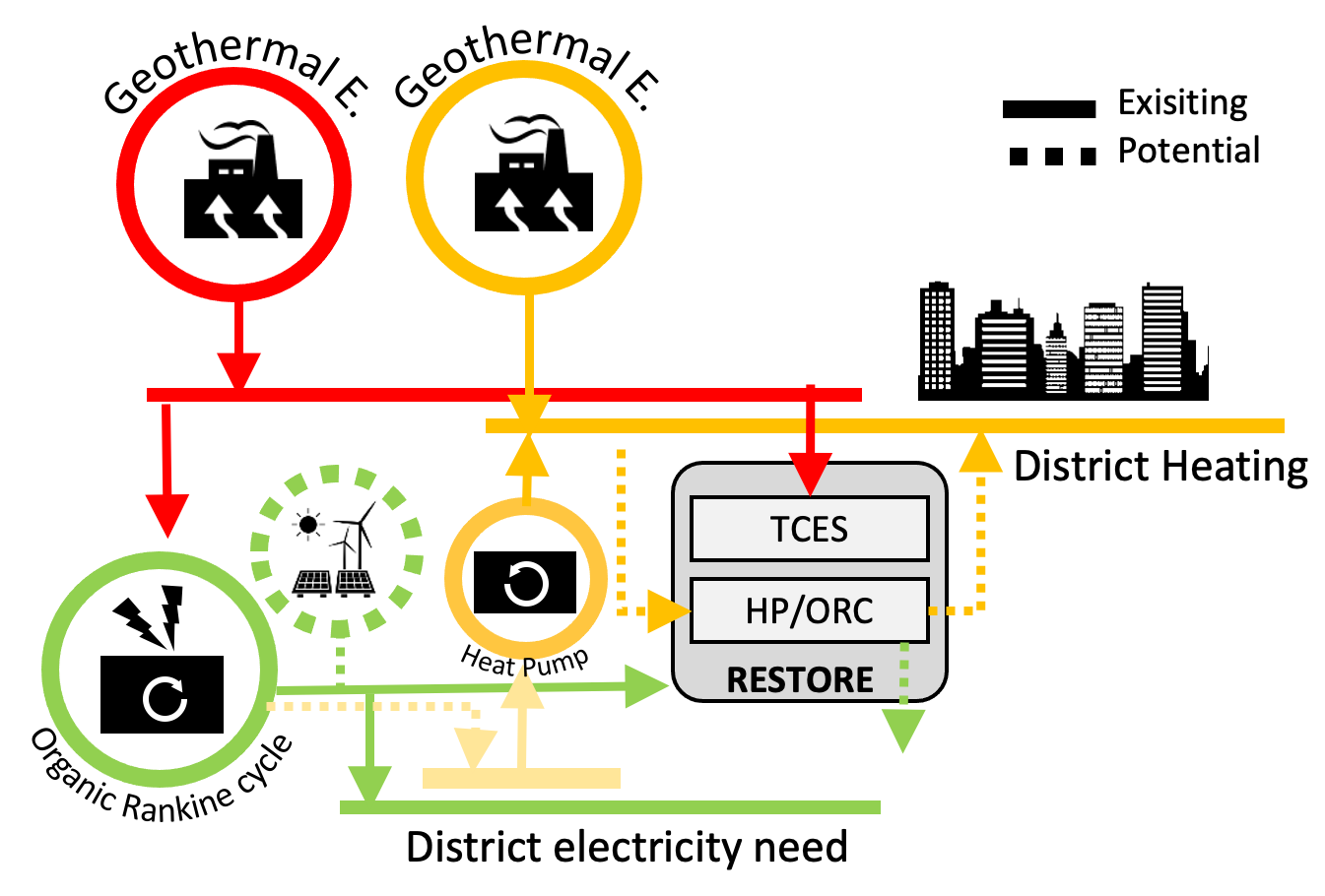

RESTORE proposed solution:

An ORC from Turboden is already installed on site to exploit geothermal hot water during the summer from a temperature of 140°C, producing a power output of 2.8 MWel. Differently from the conventional geothermal steam turbines, the ORC process uses low-to-high enthalpy geothermal fluid to preheat and vaporize a suitable organic working fluid within a closed loop:

- The organic fluid vapor rotates the turbine coupled to the electric generator.

- The exhaust vapor flows through the regenerator and condenser cooled by air or water.

- To complete the closed-cycle operation, the organic working fluid is then pumped again.

In such way the ORC turbine is not in contact with the geothermal fluid, which remains enclosed in the heat exchangers. That allows a full reinjection of all the brine and steam condensation with zero emissions to the ambient. The aim is to further increase the geothermal heat exploitation. Therefore, Turboden will study a large HP in order to achieve higher flexibility in terms of heat and power production as well as increased geothermal utilisation. The energy contained in a shallow aquifer at low temperature can feed a LHP and supply heat to a district energy network at higher temperature.

RESTORE proposed solution Holzkirchen

Community addressed:

The Holzkirchen community works have been providing the market with water and energy for more than a century. Since 1894 the company has developed into a modern, medium-sized service provider company. It has successfully faced numerous challenges, the growing population, technical progress and economic necessities. Since 1985, the business areas have expanded by supplying the community with natural gas and in 1992 with district heating.

Use Case VI - Milan, Italy

- Use-Case Area of Application: this use case aims to exploit RESTORE in small-scale DHC networks.

- Expected goals for achievement: apply the RESTORE concept to a small DHC network available at Politecnico di Milano campus and representative of small size decentralized solutions.

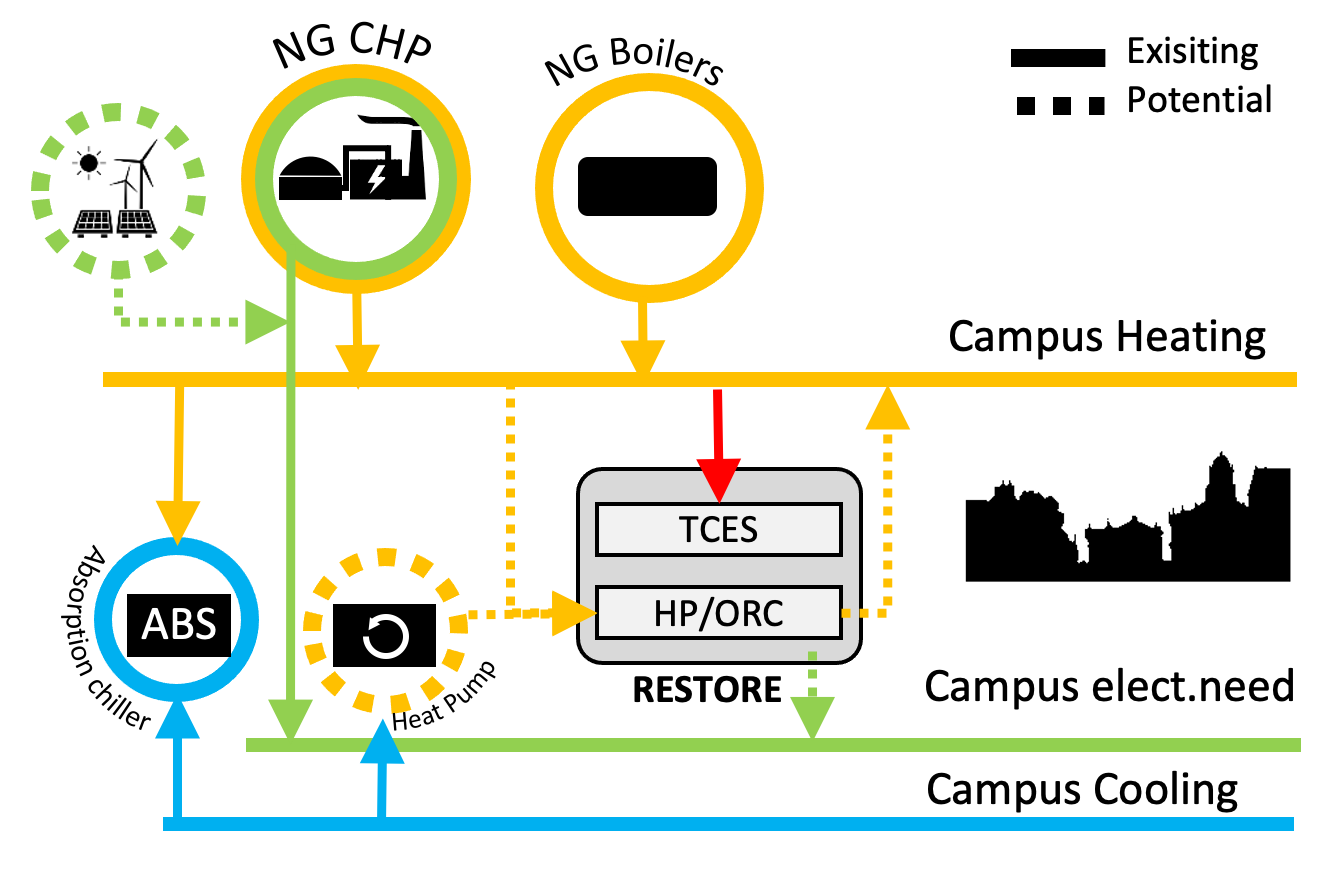

Use Case Description:

Politecnico di Milano adopts a small DH network to provide electricity and heat to a relevant fraction of campus offices, classrooms and laboratories serving approximately 120.000 m2. Moreover, cooling is also provided to some buildings during the summer season. Maximum thermal power request is around 15 MWth and thermal plant of the DHC encompasses three natural gas boilers of 6 MWth each and one natural gas internal combustion engine in CHP configuration able to provide 2 MWel plus 1.8 MWth. Cooling power 1.25 MW is generated by one absorption chiller (LiBr) exploiting CHP unit waste heat. The CHP unit is operated in thermal load following and most of electrical energy (80%) is for internal consumption while the remaining (20%) is sold to the grid. Annual hours of operations of the CHP unit thanks to the integration with the cooling network is around 5000 h.

In addition to the DHC network, the Energy Department of Politecnico di Milano located in Bovisa Campus can also provide accurate information on the availability of solar PV energy thanks to the availability of PV panels of different technologies for a total 75 kWel and a storage system constituted by 70 kWh Lithium-Ion Samsung battery. All the quantities related to DHC network, the thermal plant operation and the PV fields are continuously monitored and detailed dataset are available for the last years of operation.

RESTORE proposed solution:

This Use Case aims to investigate the role of RESTORE technology in small decentralized DHC networks and to understand the constraints in terms of space in urban contexts. First an evaluation of fuel shifting from natural gas to biogas will be investigated, then the RESTORE concept is implemented understanding the synergies with district cooling operation and RES integration. Final results assess the environmental and economic sustainability of seasonal thermal storage.

Community addressed:

Politecnico di Milano is composed of seven campuses distributed in the cities of Milano (Leonardo and Bovisa campuses), Como, Lecco, Cremona, Mantova and Piacenza. The Use Case VI considers the DHC network that serves the Leonardo and Bovisa Campuses in Milan which is an example of an independent network in a city largely served by a centralized district heating.

Use Case I – Brønderslev, Denmark

Use Case I deals with a residential and industrial DH with biomass and solar collectors in Denmark

- Use Case Area of Application: district heating for the city of Brønderslev, biomass and solar collectors as renewable technologies to provide heat to the district.

- Expected goals to be achieved: maximization of renewable energy integration in the district and optimum waste heat utilization from local industry for highly efficient seasonal storage of electricity.

Use Case II – Gmunden, Austria

Use Case II deals with the integration of different heat sources into DH of a cement factory in Austria

- Use Case Area of Application: analysis of potential configurations of integrating the RESTORE technology into the cement production plant and its relation to the neighbouring heat consumers.

- Expected goals for achievement: maximization of renewable energy integration and optimum WEH utilization from the factory for highly efficient seasonal storage of electricity using RESTORE.

Use Case III – Ružomberok, Slovakia

Use Case III integrates RESTORE with different heat sources in DH of a paper mill in Slovakia

- Use Case Area of Application: Analysis of potential configurations for integrating the RESTORE technology into plants of the Pulp and Paper Industry connected to DH and RES.

- Expected goals for achievement: Maximize the renewable energy integration and optimize WEH utilization from the factory for highly efficient seasonal heat storage.

Use Case IV – BRESCIA, Italy

Use Case IV deals with the integration of different heat sources into DH of a steel industry in Italy

- Use Case Area of Application: the use case will apply the RESTORE concept to a DHC network linked to one of the largest electric arc furnace steel mills in Italy

- Expected goals for achievement: achieve higher efficiency of Alfa Acciai production process, improve HP utilization during summer season and increase share on local DH.

Use Case V – Holzkirchen, Germany

Use Case V concerns the district heating with geothermal technology in a plant in Germany

- Use Case Area of Application: the use case will apply the RESTORE concept to a DHC network (local utility of Holzkirchen) with geothermal technology.

- Expected goals for achievement: maximization of the geothermal heat exploitation and optimum WEH utilization for highly efficient seasonal storage of heat.

Use Case VI – Milan, Italy

Use Case VI deals with a small-scale DHC network of POLIMI university campus in Italy

- Use Case Area of Application: this use case aims to exploit RESTORE in small-scale DHC networks.

- Expected goals for achievement: apply the RESTORE concept to a small DHC network available at Politecnico di Milano campus and representative of small size decentralized solutions.